Part-time, participatory, ecological

Modern timber industry in the Bern region

The timber industry is regarded as sluggish and not very innovative. Unfairly so: Three Bern-based carpentry companies are adding value to local raw materials in peripheral regions and offering future-oriented working models. This is demonstrated by research conducted by the Department of Economic Geography at the University of Bern.

The smell of resin and sawdust in the reception area makes it clear: The name of the game here is wood. And you know, at the latest, you have arrived in the woodworking sector once you have shaken hands with Jürg Hirschi – a man 1 meter 98 cm tall with a handshake that is somewhere between strong and painful. Hirschi is Chairman of the Board of Directors of the two companies Zimmerei Hirschi and Truberholz. Offering a total of 90 jobs, the two joint-stock companies are of central economic importance to the Upper Emmental municipality of Trub, which has a population of more than 1,200 people.

Industrial building as a business card

If you think of carpentry, you might imagine a gloomy shed with a deafening circular saw. Instead, the boss leads us into a spacious industrial hall, which was completed in 2015. The light-filled space is 50 meters long, 30 meters wide and 16 meters high at the ridge. The production facilities are the three-dimensional calling card of the dual company: The fir and spruce wood – a total of 1,000 cubic meters were used here – comes from Trub itself. Even the cement for the concrete floor was mixed in the local municipality’s plant. “Half of the municipality of Trub is covered by forest. We take advantage of these short distances,” explains Hirschi, who is also a trained farmer and values all things local and traditional.

Investing in innovation

But the company is also committed to innovation. In 2015, a carpenter from Eastern Switzerland raved about the new system his father had developed for producing house wall modules. The highlight: Even boards of the less popular C wood grade can be assembled to form modules 18 to 24 centimeters thick, which can then be used as walls and roofs for houses. Instead of glue or screws, solid wooden dowels hold the six to eight layers in place. It cost one and a half million francs to acquire the machine manufactured in Toggenburg. In order to keep the bank loan as low as possible, the entire value chain – forest owners, sawmills and employees – participated in the risk investment.

It took several years before the new method of constructing house walls using solid wood and no glue or metal fasteners attracted enough attention for the plant to start yielding a profit. Today, the two carpentry shops process 2,000 cubic meters of softwood each year, cut to size and dried in five neighboring sawmills. According to Hirschi, the beech wood dowels alone, which hold the six to eight layers in place, would make a 50-kilometer-long rod per year.

Part-time work is also booming in the timber industry

“The Truberholz example shows that innovative ideas also have a chance in the supposedly sluggish timber industry,” explains Miriam Hug. In her research work ending in 2025, the doctoral student at the Institute of Geography at the University of Bern examined the world of work in 86 Bern-based companies in the wood industry. She examined 24 of them in terms of their transformative potential, thus asking how far these companies could make the region more environmentally friendly, socially just and economically stable in the long term. “The evaluation has shown that this down-to-earth industry is forward-looking, for example when it comes to social added value or creating employment in peripheral locations.” In addition to the University of Bern, the Wyss Academy for Nature, which conducts research on the topic of “Developing regional forest and wood value chains” at the Bern Hub, is also participating financially in the project.

Truberholz AG is one of the companies that the doctoral student examined in more detail. The innovative technology, in which computer-aided construction planning and state-of-the-art CAD technology are a must, creates steady sales for local wood. The personnel policy is also in line with the times, with part-time work a popular feature: Twenty-five of the 90 permanent employees take a "daddy's day" once a week, run a farm on the side or hold a political office, which means they do a shorter working week in their primary job. The modern company attracts many apprentices, and the company currently offers 23 apprenticeships in carpentry and building construction planning. Sales are also stable: Trub is increasingly producing wooden elements not only for single-family homes, but also for three- and four-story buildings.

A delicate touch – in restructuring and personnel management

Röthlisberger Zimmerei AG still offers 40 jobs, including nine apprenticeships. The fifth generation of the family business has been rooted in the region – here in Bowil, halfway between Trub and Bern – for 111 years. Its specialty is the conversion of those farms that are no longer used for production, but are converted into purely residential space in the spill area. The company owned by Michael Röthlisberger and Jürg Ramseier also manufactures components for listed buildings.

The individually prepared elements for interior finishing are already neatly prepared on a flatbed in the storage room, protected against the weather and sunlight by a plastic sheet. The load will soon be collected from the truck and transported to the construction site. There, it can be installed efficiently because it is ready to go. In addition to the local wood – two years ago, the company took over a sawmill two kilometers away – the most important asset is the staff. Röthlisberger is aware of this and takes care of them: “Once a week, I openly inform the team about the order backlog and upcoming projects,” says the owner. And every day before work starts at 6:30 a.m., his office door is open for personal matters.

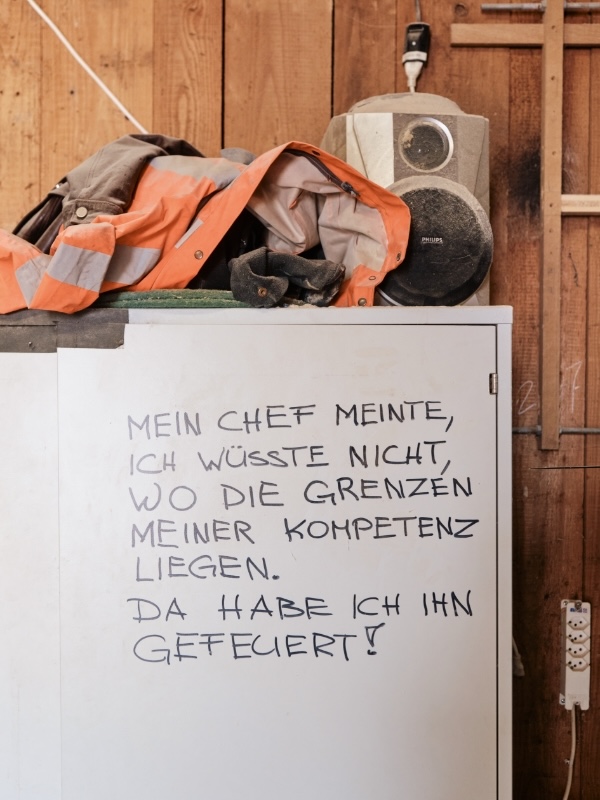

Where local music plays

Röthlisberger cannot complain about a shortage of apprentices, some of whom are women. “There is still a sense of professional pride in the timber industry that has become rare elsewhere,” he says listing this as one possible reason for this attractiveness. In addition, the company is often recommended by previous apprentices. Röthlisberger has created a discreet advertising medium for his company with the attic of the factory building, which was extended in 2015: It houses practice and concert rooms, which are rented out by several local music ensembles and where weekly rehearsals take place. “The screedis unsuitable for production and our parking lot is empty in the evening anyway. In addition, the municipality did not have any meeting rooms,”explains Röthlisberger, who makes music himself in his free time, justifying his commitment to the community. His approach to reducing working hours is also modern: Part-time makes planning a little more complicated. But those who work less often do so with great dedication.

Magazine uniFOKUS

The changing world of work

This article first appeared in uniFOKUS, the University of Bern print magazine. Four times a year, uniFOKUS focuses on one specialist area from different points of view. Current focus topic: The changing world of work.

Where the customer lends a hand

Tobias Fehr can confirm this from his own experience: “On the three days a week that I work, I do it in a very focused and efficient manner, the days are busy.” Fehr is CEO of Querbau GmbH, as can his two male colleagues and one female colleague: Anyone who works at Querbau GmbH holds a stake in the company. Only the two apprentices currently have to adhere to hierarchies.

Working under enormous time pressure and unfair working conditions were the reason why Fehr founded Querbau GmbH eight years ago together with Andreas Ferrazzini, whom he met at vocational school. Prior to that, the two of them had completed a degree in architecture and engineering, respectively. After becoming fathers, they further reduced their initial workload from 80% to 60%. It is still the case that in the owner quartet – today carpenter Sissel Størseth Haarr and architect Raphael Fitz are also part of the collective – everyone does everything. This requires a lot of coordination and sometimes a Signal message in their free time. In return, this way of working brings variety and also makes it possible for them to represent each other. A standard salary is paid; at the end of the year, company profits are distributed according to the hours worked.

“Innovative ideas also have a chance in the supposedly sluggish timber industry.”

Miriam Hug

The relationship with customers is exceptional: If you like, you can lend a hand under the guidance of the experts and thus reduce costs. Ecology is important: Querbau GmbH processes a lot of natural wood from the region, but not much glue and other foreign substances – but Fehr does not like to advertise big time with these services. The order situation is good anyway, and instead of marketing, what they need is a move. At the moment, Querbau GmbH is still on the Aebimatte in the city of Bern, right next to the SBB railway line and in the immediate vicinity of a vegetable depot, a potter and three other workshops. In summer, the site will be cleared for personal use. The company will then move to Lorraine, once again to an environment of like-minded companies. A lot of the transverse construction will remain the same in the new location: Self-government, the joy of wood as a beautiful material and a certain pride that the industry radiates in this country.

Diversity as a good prerequisite

“In my research, I identified five types of companies in the wood industry that have different transformative positions,” explains Miriam Hug. While some are tinkering with particularly innovative products, others rely on strong roots in the region, use local raw materials or take particular care of their employees.

Even though the forestry and timber industry in the canton of Bern only accounts for 1.8% of gross value added, Hug feels such soft factors are important elements to ensure that the professional group is well equipped for the future: “It provides attractive jobs in structurally weak areas and contributes to sustainable development thanks to the regional raw material wood.”

Regional economy

Learning from each other

“Innovation is usually only associated with technology, but this definition does not go far enough,” says Heike Mayer, Professor and Head of the Economic Geography unit at the Institute of Geography and Vice-Rector for Quality and Sustainability Development at the University of Bern. For Mayer, who oversees Miriam Hug’s “Transformative Companies” research project, a company can also make its mark by not only focusing on the quickest possible profit, but also focusing on traditional values such as quality, meaningfulness and social responsibility. Hug’s work also shows that transformative companies tend to be progressive in several areas at the same time. In addition to the regional supply of raw materials and energy, this also includes, for example, careful handling of the workforce. The possibility to work part-time, for example, alleviates the current shortage of skilled workers and enables employees to reduce their personal working hours and maintain a more adequate lifestyle.

According to Mayer, the public sector can support a transformative economy in two ways: “The timber industry in the Austrian state of Vorarlberg, which was also investigated in the project, demonstrates how important platforms are for collaboration, exchange, coordination and learning from one another.” In addition, state institutions should set an example with their own procurement practices and ensure that regional offers are also considered.

Subscribe to the uniAKTUELL newsletter

Discover stories about the research at the University of Bern and the people behind it.